Business Innovation in the Modern Era: Leveraging Electronics, 3D Printing, and Concrete Mixing Plants for Unmatched Growth

In the rapidly evolving landscape of global commerce, businesses that harness the latest technological advancements position themselves ahead of competitors and unlock new avenues for growth. Among these groundbreaking innovations, the integration of electronics, 3D printing, and specialized manufacturing machinery such as the concrete mixing plant have revolutionized various industries. This comprehensive guide explores how these technologies are synergistically transforming business operations, enhancing productivity, and fostering sustainable development.

Understanding the Core Technologies Transforming Business Today

Electronics: The Bedrock of Modern Business Solutions

Electronics serve as the foundation of all technological innovations currently shaping industries. From smart control systems to advanced sensors, electronics enable automation, precision, and data-driven decision-making. Businesses investing in cutting-edge electronic components benefit from increased efficiency, reduced operational costs, and improved quality control.

- Automation and Control Systems: Electronic control units automate complex manufacturing processes, ensuring consistency and reducing human error.

- IoT Integration: Internet of Things (IoT) devices provide real-time data monitoring, predictive maintenance, and system optimization.

- Smart Sensors: Enhance safety, quality, and production speed by providing accurate environmental and operational data.

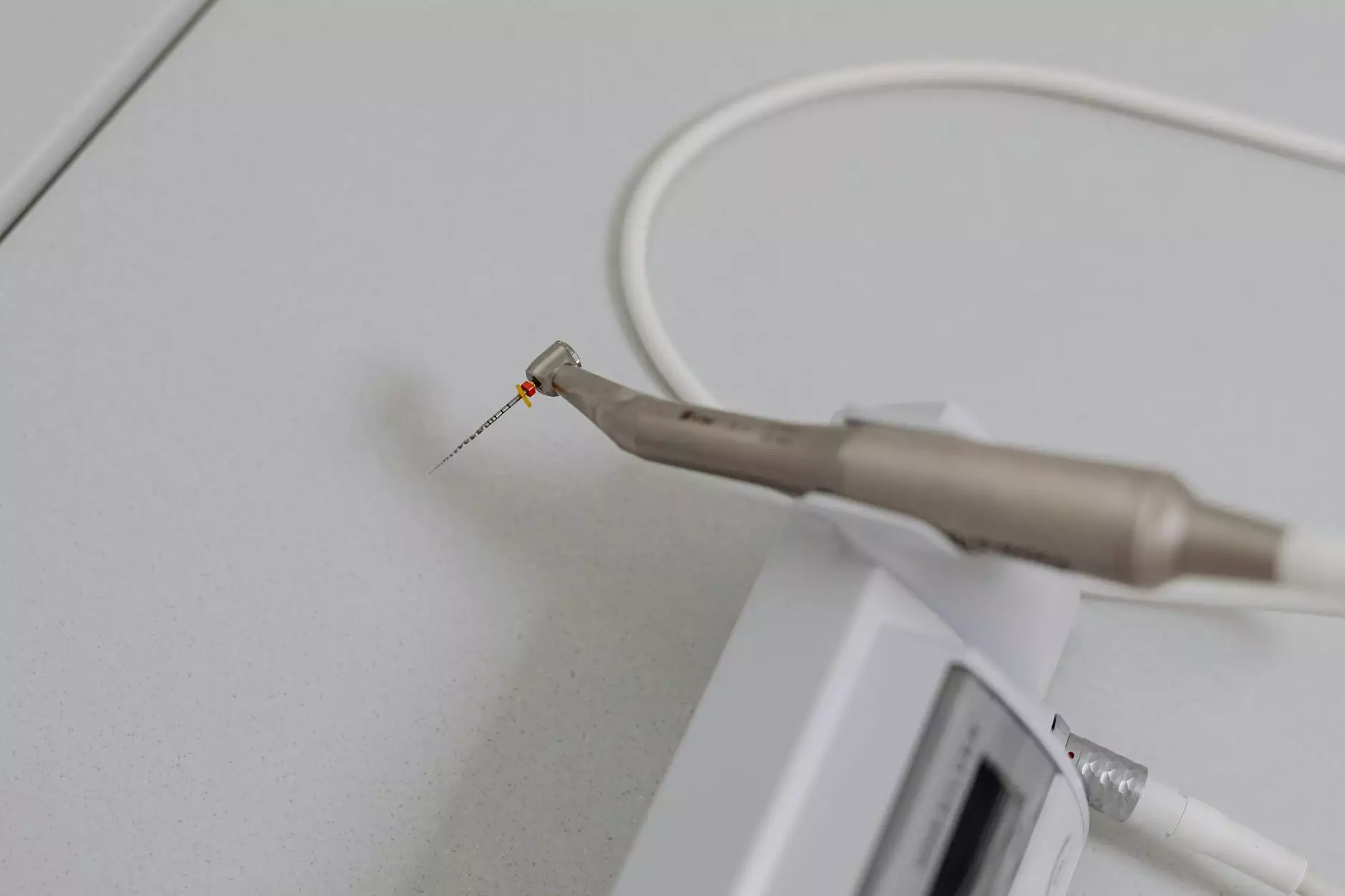

3D Printing: Redefining Manufacturing and Prototyping

3D printing has emerged as a revolutionary technology that enables the creation of complex, precise, and customized components rapidly and cost-effectively. Its applications in prototyping, small-batch production, and even large-scale manufacturing are unparalleled. In particular, 3D printing's ability to produce intricate structures with minimal waste makes it a vital asset for innovative business models.

- Enhanced Design Flexibility: Create detailed prototypes and final products with complex geometries that traditional manufacturing cannot easily achieve.

- Cost Savings: Reduce material waste and tooling costs, making small runs economically feasible.

- Rapid Prototyping: Accelerate product development cycles, bringing innovations to market faster.

The Role of Concrete Mixing Plants in Modern Business Infrastructure

What Is a Concrete Mixing Plant?

At the heart of many construction and infrastructure projects lies a concrete mixing plant. This specialized machinery blends raw materials—cement, aggregates, water, and additives—to produce high-quality concrete efficiently. With advances in automation and electronics, modern concrete mixing plants are highly sophisticated, offering precise control over mixture proportions and quality.

Why Modern Industries Rely on Concrete Mixing Plants

Concrete remains a staple in construction, infrastructure development, and manufacturing. The concrete mixing plant offers several advantages that align with contemporary business needs:

- Consistency and Quality: Automated systems ensure uniformity in strength, durability, and finish.

- Efficiency and Speed: High-capacity plants can produce large volumes of concrete in a short time, accelerating project timelines.

- Flexibility: Ability to produce diverse concrete mixes tailored to specific project requirements, including specialty mixes with additives or specific colorants.

- Sustainability: Optimized mixing processes reduce waste and improve resource utilization, aligning with green business practices.

Innovative Business Applications Integrating Electronics, 3D Printing, and Concrete Technology

Advanced Construction: Building Smarter and Faster

Modern construction companies leverage concrete mixing plants equipped with IoT sensors and automation to ensure real-time quality monitoring. Coupled with 3D printing for architectural components and electronic controls for process management, construction projects are becoming faster, safer, and more precise. For example, intricate architectural elements can be 3D printed using specially formulated concrete, leading to innovative designs that were previously impossible or prohibitively expensive.

Manufacturing Customized Components with 3D Printing and Electronics

Small-to-medium-sized enterprises (SMEs) utilize 3D printing integrated with electronics for rapid prototyping and production of custom parts. When combined with automated concrete mixing plants for infrastructural components, firms can produce tailored solutions swiftly, reducing lead times and opening new markets for bespoke products.

Sustainable Infrastructure Development

Sustainability is a central pillar of future business strategies. Electric-driven concrete mixing plants, paired with renewable energy sources, minimize carbon footprints. Using sensors and electronic controls, plants operate with high efficiency, reducing energy consumption and waste. Additionally, 3D printing allows for the reuse of surplus materials to minimize environmental impact.

Investing in Cutting-Edge Technology: How to Stay Ahead

Strategic Investment in Electronics and Automation

Businesses should prioritize the integration of state-of-the-art electronics—such as IoT, automation controllers, and sensors—into their manufacturing and construction processes. This investment ensures continuous operational improvements, predictive maintenance, and data-driven decision-making, which are essential for staying competitive.

Adopting 3D Printing for Product Innovation

Implementing 3D printing technology enables companies to experiment rapidly with new designs, reducing the time-to-market and fostering innovation. Collaboration with technology providers and ongoing research into new materials can unlock higher efficiency and broader application scopes.

Upgrading to Smart Concrete Mixing Plants

Modern concrete mixing plants embody Industry 4.0 principles—fully automated, connected, and smart. Businesses investing in such systems can achieve unparalleled precision, scalability, and environmental compliance, positioning themselves as industry leaders.

The Future of Business Enabled by Tech-Driven Construction and Manufacturing

The landscape of global business is heading toward a paradigm where technological integration is not optional but essential. Electronics drive automation and data intelligence; 3D printing fosters adaptability and customized production; and concrete mixing plants support sustainable and efficient infrastructure development. Together, these technologies enable industries to attain higher levels of productivity, innovation, and environmental responsibility.

Conclusion: Embracing Innovation for Long-Term Success

Business success in the digital age hinges on innovation and strategic adoption of emerging technologies. Companies that leverage electronics for smart management, utilize 3D printing for design flexibility, and operate advanced concrete mixing plants for reliable production will stand at the forefront of their industries. By integrating these technologies seamlessly, businesses can unlock new opportunities, optimize operations, and make a positive impact on society and the environment.

Partner with Industry Leaders for Your Business Innovation Journey

If you're looking to elevate your business through these transformative technologies, polygonmach.com offers comprehensive solutions in electronics, 3D printing, and concrete mixing plants. With decades of experience, cutting-edge equipment, and global expertise, they empower businesses to innovate and grow sustainably.