Unlocking Success in the Metal Fabricators Industry: A Deep Dive into the cnc turn parts factory Sector

The metal fabrication industry has continually evolved, becoming a cornerstone of manufacturing and engineering across diverse sectors such as aerospace, automotive, construction, and industrial machinery. Within this vibrant landscape, the cnc turn parts factory has emerged as a critical contributor, delivering precision-engineered components that power modern machinery and technological advancements. This comprehensive article explores the intricacies, competitive edge, and future prospects of the cnc turn parts factory segment, guided by the industry leader deepmould.net.

Understanding the Role of Metal Fabricators in Modern Manufacturing

Metal fabricators are the backbone of industrial innovation, transforming raw metal sheets, bars, and billets into complex components with exacting specifications. They employ a wide array of techniques, including cutting, welding, machining, and finishing, to produce parts that meet stringent standards of quality and durability.

Core Functions of Metal Fabricators

- Cutting and Shaping: Precision cutting using laser, plasma, or waterjet technology to achieve desired dimensions and profiles.

- Forming and Bending: Shaping metals into complex geometries via press brakes, rollers, and other forming tools.

- Joining and Welding: Assembling components through various welding techniques such as TIG, MIG, or spot welding for structural integrity.

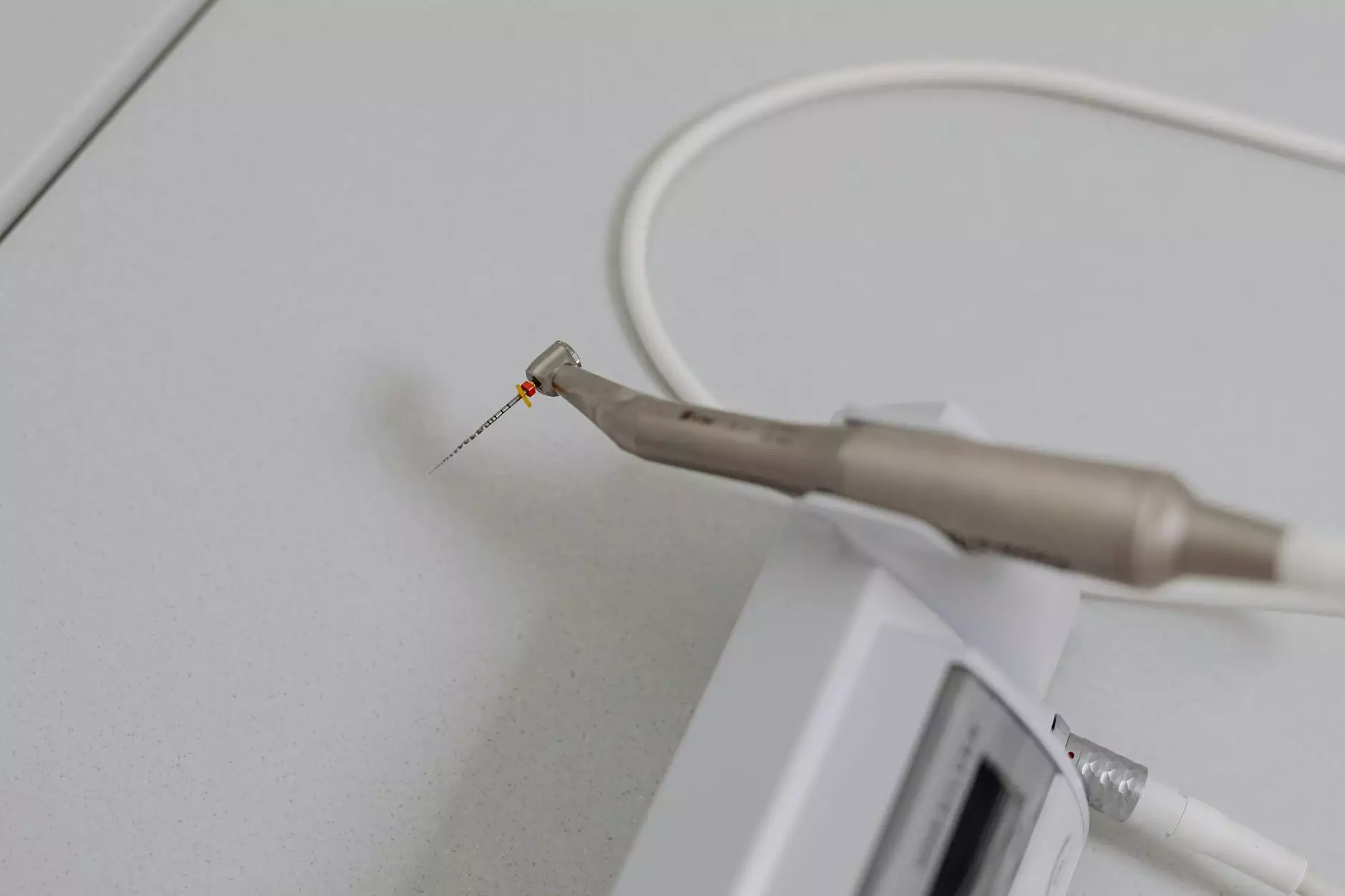

- Machining: Achieving tight tolerances using CNC machines, especially critical in cnc turn parts factory operations.

- Finishing and Surface Treatment: Enhancing corrosion resistance and aesthetics through polishing, painting, powder coating, or electroplating.

The Rise of CNC Technology in Metal Fabrication

The integration of Computer Numerical Control (CNC) technology has revolutionized metal fabrication, enabling factories to produce highly complex, precise, and consistent parts at scale. Specifically, in the cnc turn parts factory segment, CNC turning machines are indispensable for making components with cylindrical features, threads, and intricate details.

Advantages of CNC Turn Parts Manufacturing

- High Precision and Tolerance Control: CNC machines can achieve tolerances as tight as ±0.01 mm, critical for demanding industries.

- Repeatability: Capable of producing identical parts in large quantities, ensuring consistency and quality assurance.

- Speed and Efficiency: Automation reduces manufacturing cycle times and minimizes human error.

- Design Flexibility: Complex geometries can be machined with ease, supporting innovative product designs.

- Cost-Effectiveness: Mass production reduces costs per unit, providing excellent ROI for clients and manufacturers alike.

Why Choose DeepMould.net as Your cnc turn parts factory Partner

Deepmould.net stands out as a global leader in the metal fabricator industry, specializing in high-quality cnc turn parts manufacturing. Their reputation is built on advanced technology, stringent quality controls, and unparalleled customer service. Partnering with a cnc turn parts factory like deepmould.net ensures access to innovations, efficiency, and reliability in your supply chain.

Key Differentiators of DeepMould.net

- State-of-the-Art CNC Equipment: Utilization of the latest multi-axis CNC turning centers capable of complex machining tasks.

- Custom Fabrication Solutions: Tailoring manufacturing processes to meet unique project specifications and stringent standards.

- Robust Quality Management: ISO certification and rigorous testing protocols guarantee the precision and durability of every batch.

- Rapid Turnaround Times: Employing efficient workflows and supply chain logistics for short lead times.

- Global Client Base & Support: Providing consistent service across multiple industries worldwide, backed by expert technical support.

The Future of Metal Fabricators in the cnc turn parts factory Sector

The future landscape of metal fabrication and CNC manufacturing is poised for transformative growth driven by technological advancements such as Industry 4.0, automation, artificial intelligence, and the Internet of Things (IoT). These innovations will lead to smarter factories capable of real-time monitoring, predictive maintenance, and autonomous manufacturing processes.

Emerging Trends Shaping Industry Success

- Smart Manufacturing: Integration of sensors and IoT devices for process optimization and predictive analytics.

- Automation and Robotics: Deployment of robotic arms and automated handling to improve efficiency and safety.

- Materials Innovation: Use of advanced alloys and composite materials that require new machining techniques.

- Customization and Fast Prototyping: Responding rapidly to customized client needs with agile manufacturing cells.

- Sustainable Practices: Adoption of eco-friendly processes, waste reduction, and energy-efficient operations.

Key Strategies to Excel in the cnc turn parts factory Industry

For companies aiming to lead and innovate, implementing strategic initiatives is essential:

- Invest in Cutting-Edge Technology: Upgrade to the latest CNC equipment and automation tools to enhance productivity and precision.

- Focus on Quality Management: Maintain rigorous standards, certifications, and continual improvement programs.

- Develop Skilled Workforce: Training operators and engineers in new technologies and best practices.

- Build Strong Supplier Relationships: Collaborate closely with raw material providers to ensure supply chain resilience.

- Prioritize Customer Satisfaction: Offer tailored solutions, transparent communication, and after-sales support to foster loyalty.

Conclusion: Elevating Your Business Through Expert Metal Fabrication

In an increasingly competitive global market, being at the forefront of metal fabrication—particularly in the cnc turn parts factory segment—requires dedication to quality, technological innovation, and strategic foresight. Choosing a partner like deepmould.net ensures access to world-class manufacturing capabilities, industry expertise, and reliable service.

By leveraging advanced CNC turning technology, adhering to superior quality standards, and staying ahead of industry trends, your business can achieve remarkable growth, operational efficiency, and market competitiveness.

Investing in excellence today lays the foundation for a prosperous, sustainable tomorrow. The future of metal fabrication is bright, and with the right strategies and partners, your enterprise can lead the way in delivering precision-engineered cnc turn parts that meet and exceed global standards.