Unlocking Innovation with Metal Laser Sintering: The Future of Art Supplies, Product Design, and 3D Printing at Arti90

In the rapidly evolving landscape of manufacturing and creative expression, metal laser sintering has emerged as a groundbreaking technology transforming industries worldwide. At the intersection of artistry, engineering, and technological innovation, this advanced process offers unprecedented precision, flexibility, and efficiency. Arti90, a pioneer in art supplies, product design, and 3D printing, leverages the power of metal laser sintering to push the boundaries of what is possible, empowering creators and manufacturers alike to turn visionary ideas into tangible realities.

What is Metal Laser Sintering? An In-Depth Look

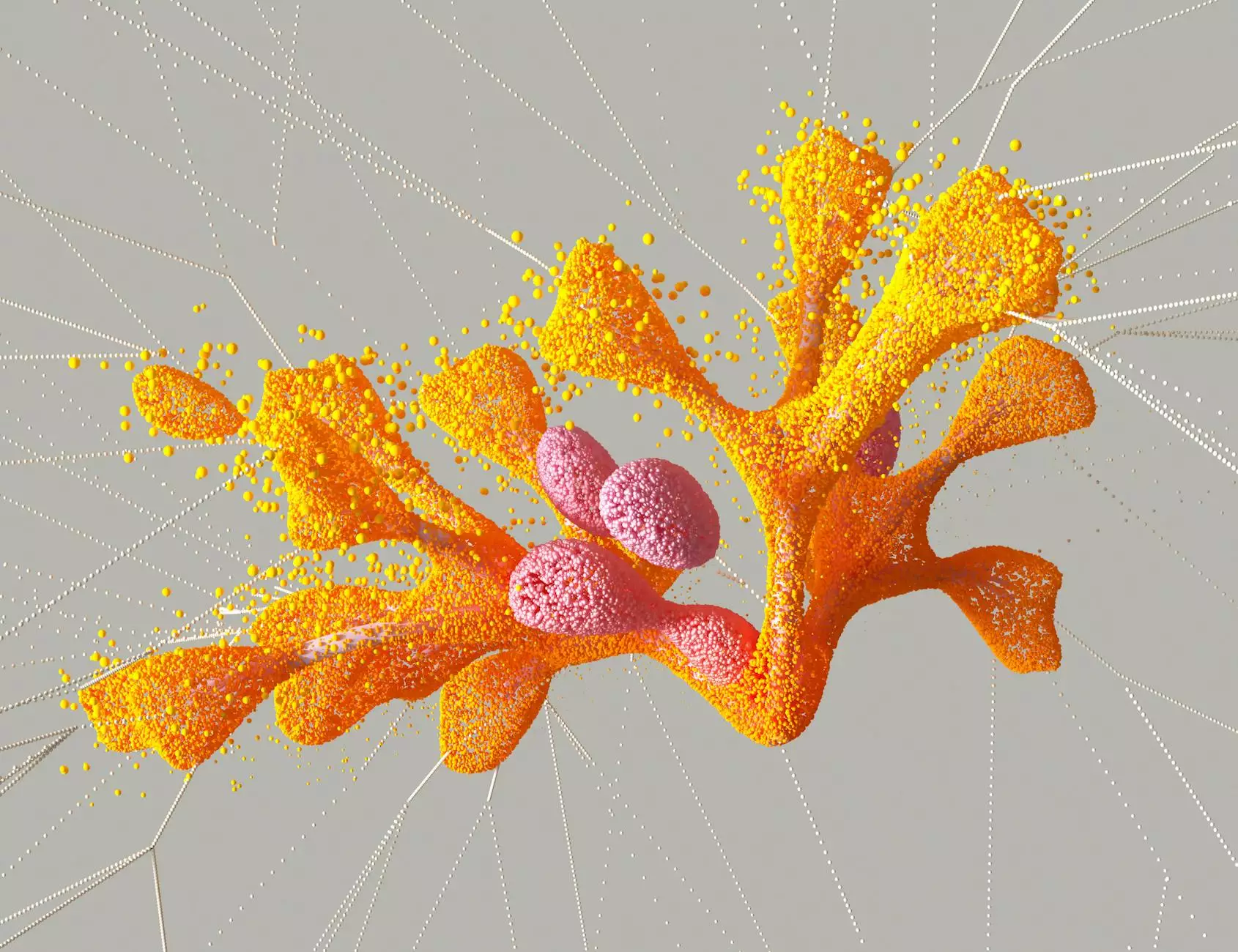

Metal laser sintering (often abbreviated as metal SLS or MASS) is an additive manufacturing process that utilizes a high-powered laser to fuse metallic powders into complex, durable parts layer by layer. Unlike traditional manufacturing methods that rely on subtractive techniques—such as milling or casting—this process builds objects directly from digital designs, providing unparalleled design flexibility and rapid prototyping capabilities.

The process begins with a precisely controlled laser beam scanning across a bed of fine metallic powder. The laser's heat causes the powder particles to melt and fuse together at targeted points, solidifying into a single, cohesive structure. After each layer is completed, the build platform lowers, and a new layer of powder is spread over the previous one, repeating until the full object is constructed.

Advantages of Metal Laser Sintering in Modern Industries

- Exceptional Design Freedom: Complex geometries, intricate internal channels, and lightweight structures are now feasible without additional tooling or molds.

- High Precision and Accuracy: Achieve tight tolerances and detailed features essential for both art installations and functional engineering components.

- Material Versatility: A diverse range of metallic powders—including stainless steel, titanium, aluminum, and precious metals—are available for various applications.

- Rapid Prototyping and Iteration: Quickly translate digital models into physical prototypes, reducing time-to-market and fostering innovation.

- Cost-Effective Small Batch Production: Ideal for limited runs, custom pieces, or bespoke art projects where traditional manufacturing would be prohibitively expensive.

- Sustainability Benefits: Minimizes material waste by only using the necessary powder and allowing for recycling of unused powders.

Transforming Art Supplies with Metal Laser Sintering

In the realm of art, metal laser sintering unlocks new creative possibilities by enabling artisans and sculptors to craft intricate, durable, and precious artworks. This technology allows for the production of bespoke jewelry, personalized sculptures, and experimental art pieces that were previously impossible or too costly using traditional methods.

For example, artists can design highly detailed models with internal cavities or delicate filigree structures, then bring these designs to life in metal with just a few finishing touches. This precision facilitates the creation of limited-edition art pieces or one-of-a-kind collectibles, blending aesthetics with technical mastery.

Revolutionizing Product Design through Metal Laser Sintering

In product design, metal laser sintering is reshaping how designers conceptualize and develop innovations. Its ability to routinely produce complex, customized, and high-performance components accelerates the entire product lifecycle—from conceptual sketches to finished prototypes and final manufacturing.

Designers benefit from:

- Rapid Development: Quickly test functional prototypes with real-world properties, reducing design flaws and improving product performance.

- Customization Capabilities: Tailor products for individual clients, niche markets, or unique use cases without significant extra costs.

- Structural Optimization: Implement topologically optimized designs that maximize strength-to-weight ratios, essential in aerospace, automotive, and sports equipment.

- Elimination of Tooling Costs: Bypass traditional molds and dies, making it economically viable to produce low-volume, highly detailed parts.

Impact of Metal Laser Sintering on the 3D Printing Industry

The advent of metal laser sintering has been a catalyst for innovation within the broader 3D printing landscape. It has expanded the scope of additive manufacturing, enabling industries to produce parts with the strength, durability, and precision comparable to traditionally manufactured metal components.

Major benefits include:

- Design Complexity: Practically no geometries are off-limits, including lattice structures, internal channels, and conformal cooling systems.

- Speed & Efficiency: Faster turnaround times from digital concept to physical object, streamlining R&D and production cycles.

- Supply Chain Simplification: On-demand manufacturing reduces inventory needs and logistics costs.

- Innovation in Medical, Aerospace, and Automotive Fields: Enabling the production of customized implants, lightweight aircraft parts, and high-performance automotive components.

Materials Used in Metal Laser Sintering

The success and application scope of metal laser sintering heavily depend on the choice of materials. Industry-leading providers now offer a broad spectrum of metallic powders, each suited for specific applications:

- Stainless Steel: Renowned for corrosion resistance, strength, and versatility. Used in jewelry, tooling, and medical devices.

- Titanium: Lightweight, biocompatible, and strong—ideal for aerospace, medical implants, and high-performance parts.

- Aluminum: Excellent strength-to-weight ratio, suitable for automotive and aerospace components.

- Precious and Nickel Alloys: Used in jewelry, electrical, and specialized industrial applications, delivering excellent thermal and electrical properties.

Why Choose Arti90 for Metal Laser Sintering?

Arti90 stands out as a leader in harnessing metal laser sintering technology for artistic, industrial, and innovative endeavors. Our commitment to quality, cutting-edge machinery, and expert consultation ensures that clients receive top-tier results tailored to their unique needs.

At Arti90, we provide:

- State-of-the-art Equipment: Latest laser sintering machines capable of handling diverse materials and intricate designs.

- Expert Support: Skilled professionals guide you through design optimization, material selection, and post-processing techniques.

- Quality Assurance: Rigorous inspection and testing ensure the highest standards for durability and precision.

- Range of Services: From prototyping and small batch production to custom art pieces and intricate jewelry manufacturing.

The Future of Business with Metal Laser Sintering

As industries increasingly adopt metal laser sintering, businesses can gain a significant competitive edge through innovation, cost reduction, and versatile manufacturing capabilities. The technology's ability to deliver complex, high-quality metal parts on demand is revolutionizing supply chains, product development cycles, and artistic expression.

Moreover, ongoing advancements—such as multi-material sintering, faster laser scanning, and even more exotic metal powders—promise to expand possibilities even further. Businesses that integrate this technology now will position themselves as leaders in their respective markets, capable of offering innovative solutions that meet modern demands for customization, speed, and sustainability.

Conclusion: Embracing the Power of Metal Laser Sintering

In a world where science and art collide, metal laser sintering emerges as a transformative force that redefines creation. Whether you are an artist looking to craft intricate metal sculptures, a product designer striving for innovative structural solutions, or a manufacturer seeking efficient, high-quality production methods, this technology offers limitless potential.

At Arti90, we are committed to harnessing the capabilities of metal laser sintering to help our clients turn visionary ideas into reality. Embrace this revolutionary technology today and elevate your business to new heights of creativity, precision, and productivity.