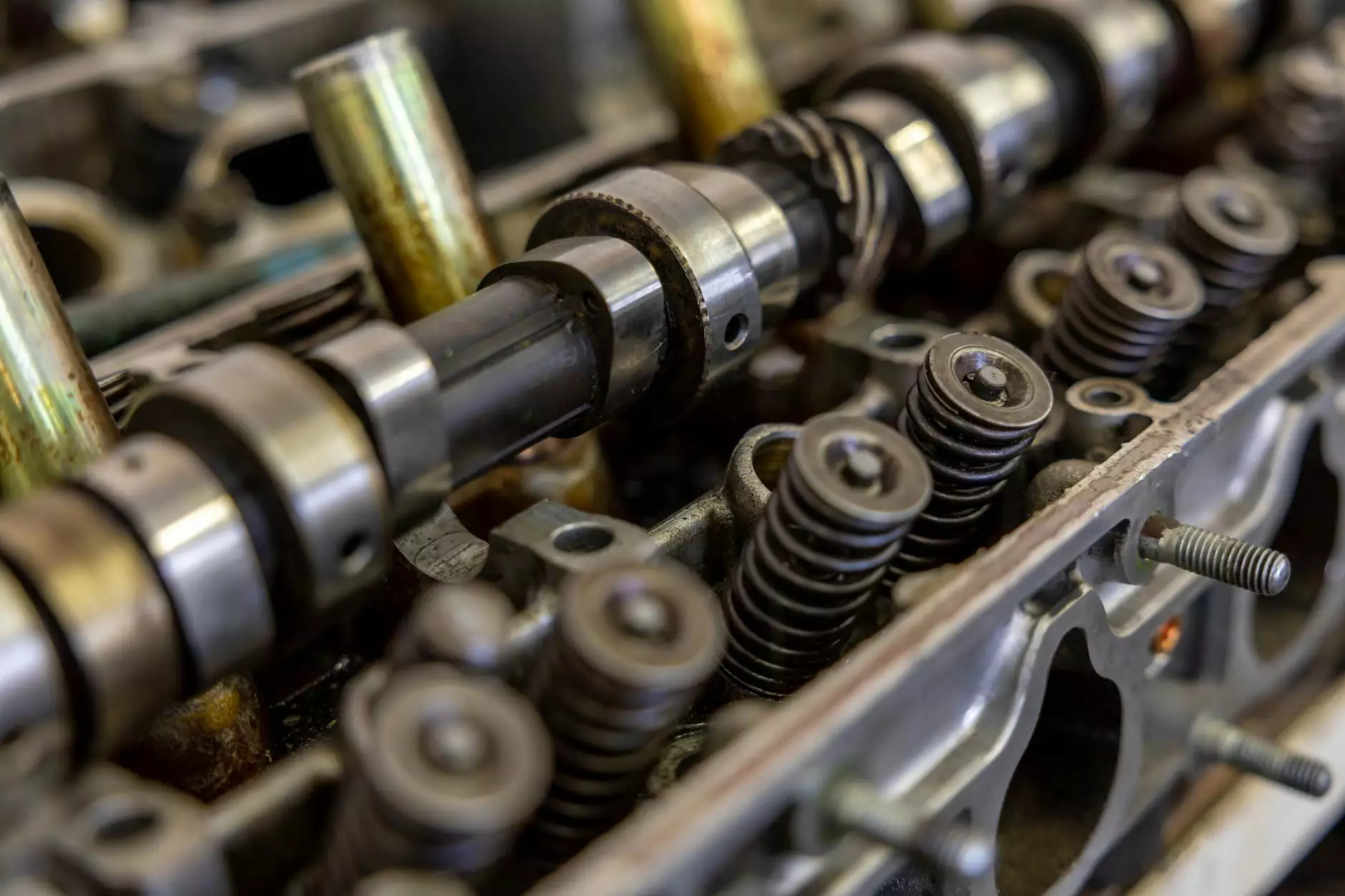

Engine Camshaft Manufacturers: Elevating Diesel Engine Performance

In the intricate realm of diesel engines, the engine camshaft stands out as a pivotal component that significantly influences the overall performance and efficiency of these robust machines. Understanding the role of engine camshaft manufacturers is crucial for anyone involved in the field of diesel engine parts and spare parts suppliers, such as client-diesel.com.

The Importance of Engine Camshafts in Diesel Engines

The camshaft serves as the heart of the engine's operation. Responsible for controlling the timing and movement of the engine's intake and exhaust valves, the camshaft impacts various engine parameters, such as power delivery, torque, and fuel efficiency. Here are some critical roles that engine camshafts play:

- Valve Timing: Ensures that the valves open and close at the right times in relation to the position of the pistons.

- Engine Breathing: Affects the engine's ability to "breathe" by optimizing the intake and exhaust flow, leading to improved power.

- Performance Tuning: Allows customization in high-performance diesels, enabling enthusiasts to tune their engine for optimal performance.

Types of Engine Camshafts

Engine camshafts can be classified into various types based on design and function. Each type serves a particular purpose and can be chosen based on specific needs:

1. Overhead Camshaft (OHC)

Overhead camshafts are prevalent in modern diesel engines for their capability to reduce engine weight and enhance performance. They typically come in two varieties:

- Single Overhead Camshaft (SOHC): One camshaft operates both intake and exhaust valves.

- Double Overhead Camshaft (DOHC): One camshaft for intake valves and another for exhaust valves, allowing for more precise valve control and performance.

2. Pushrod Camshaft

Primarily found in older engine designs, pushrod camshafts utilize a series of pushrods to transfer motion from the camshaft to the valves. Though less common today, their simplicity and reliability are notable.

3. Solid vs. Hydraulic Camshafts

These camshafts differ in design and operation:

- Solid Camshafts: Offer a more direct valve control experience, often preferred in performance applications.

- Hydraulic Camshafts: Use hydraulic lifters to adjust valve clearance automatically, leading to quieter operation and less maintenance.

Choosing the Right Engine Camshaft Manufacturer

When it comes to sourcing these essential components, selecting the right engine camshaft manufacturers is vital. Here are factors to consider when making this important decision:

1. Quality and Standards

Reputable manufacturers adhere to strict quality control measures and industry standards. Look for certifications that indicate a commitment to excellence and reliability.

2. Experience and Expertise

Manufacturers with years of experience in producing engine camshafts for diesel engines are often better equipped to meet complex demands and specifications. Their expertise can be invaluable in ensuring optimal performance.

3. Customization Options

High-end manufacturers understand that one size does not fit all. The ability to customize camshafts to suit specific engine designs or performance goals is a significant advantage.

4. Customer Support and Service

Reliable customer support is critical, especially when dealing with complex engine components. Responsive manufacturers who provide excellent post-sale service can greatly enhance your purchasing experience and confidence in the product.

Leading Engine Camshaft Manufacturers

There are numerous manufacturers in the market, but a few stand out due to their reputation for quality and innovation in the realm of diesel engine parts:

- Company A: Known for precision engineering and a robust range of performance camshafts that cater to various diesel applications.

- Company B: Specializes in high-performance camshafts, providing customized solutions for racing and heavy-duty applications.

- Company C: A long-standing player in the industry, recognized for their strict quality assurance processes and wide distribution network.

How Engine Camshafts Affect Diesel Performance

The relationship between the camshaft and overall engine performance cannot be overstated. Here’s how the selection and installation of a camshaft can influence diesel engine behavior:

1. Increased Power Output

By optimizing valve timing and lift, a performance camshaft can significantly enhance the power output of a diesel engine. This is particularly advantageous in applications requiring high torque and horsepower, such as in trucks and heavy machinery.

2. Efficiency and Fuel Consumption

With precise valve timing, a well-designed camshaft can improve the engine’s efficiency, resulting in better fuel consumption rates. This aspect is crucial for operators looking to reduce operating costs while maximizing productivity.

3. Engine Longevity

Quality camshafts reduce wear and stress on engine components, promoting better overall health and longevity of the engine. Engines equipped with high-quality camshafts generally experience fewer breakdowns and repairs, contributing to lower total cost of ownership.

The Future of Engine Camshaft Manufacturing

As technology continues to evolve, so too does the field of engine camshaft manufacturing. Here are some anticipated trends and advancements:

1. Advancements in Material Science

The development of new materials promises better durability and performance. Lighter and stronger materials can help reduce engine weight and improve speed without sacrificing strength.

2. Integration of Technology

With the rise of smart technologies, manufacturers may begin integrating sensors within camshafts to provide real-time data on engine performance. This data can help in adjusting the performance dynamically during operation.

3. Sustainability Considerations

As industries shift towards sustainability, engine camshaft manufacturers are likely to focus on reducing environmental impact by adopting eco-friendly production practices and materials.

Conclusion

The role of engine camshaft manufacturers cannot be overlooked in the quest for superior diesel engine performance. By understanding the intricacies of camshaft design, types, and the significance of selecting the right manufacturer, operators and enthusiasts can enhance their diesel engine’s efficiency, power, and longevity. For those seeking high-quality engine components, client-diesel.com offers a wide range of diesel engine parts, ensuring you have access to the best in the industry.